Milling Tandems

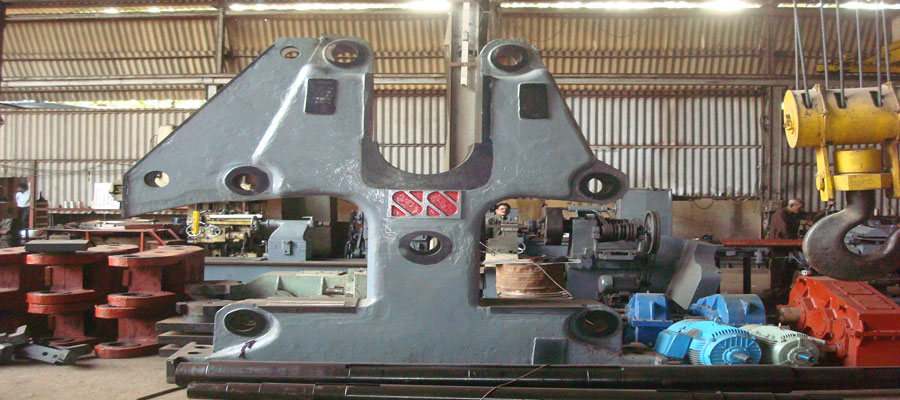

SS Engineers have always stood apart on the strong foundation of engineering, experience and enterprise. We have indigenous designed a complete sugar mill, meeting world class standards, the integral five/six roller mill . SS Engineers can design an economic and extraordinary milling plant of any capacity. The milling tandems are available with drives at the option of the client and offer complete flexibility.

We can provide mill tandem from 20" X 40" to 50" X 100"

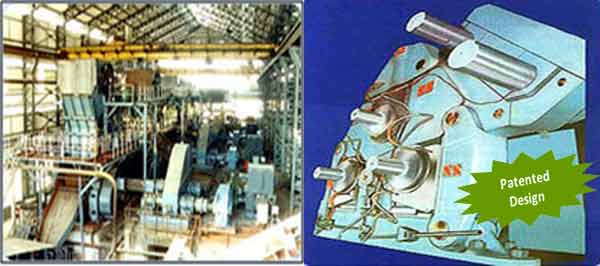

Super Structured Mills (Five/Six Roller Integrated) Patented Mill.

We are proud to state that Super structured mill is first of its kind technology the outcome of our rigorous R & D efforts.

The Super Structured Mill has been designed by SS Engineers, as an answer to the problems of existing Five/Six Roller Mill designs offered by other mill manufacturers. The disadvantages of long pressure chutes, large contact angles and complicated constructions, which result in low throughput, low efficiencies, more power requirement, operational and maintenance problems of the mill, are well taken care of, in our Super Structured Mills. We are proud to state that the Super Structured Mills is FIRST OF ITS KIND technology developed, the outcome of our rigorous research & development efforts. Some of the unique features are:

- The Feed Roller can be easily removed without dismantling the pressure chute or pressure feeder unit.

- Extremely short pressure chute.

- Least possible contact angle which leads to efficient mill feeding.

- Lowest power consumption for given crushing.

- Compact, simple and robust design.

- Juice drainage from sides.

- Lesser maintenance.

- Split pins for easy removal and refitting.

- Tailor made SS Mills (Five/Six Rollers) to suit existing foundation.

The Super Structured 5/6 Roller Mill that has revolutionized the Milling concept in India

Till date SS Engineers has supplied and have under commissioned more than 350 patented mills from 550 mm X 1200 mm to 1270 mm X 2540 mm.

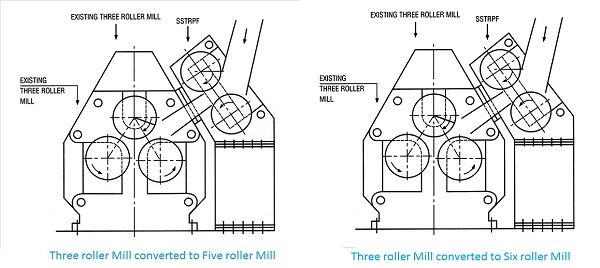

The SSTRPF / SSGRPF System (Heavy Duty)

Although the TRPF/GRPF milling system increases the crushing capacity, it is experienced that conventional TRPF/GRPF technology, which is developed abroad, is not convenient in India . This is because it requires extensive modifications in the foundations, drives, gearing. It also has a long pressure chute, which results in larger contact angle and uneven mill feeding.

SS Engineers has developed the SSTRPF (Short Space Toothed Roller Pressure Feeder)/SSGRPF (Short Space Grooved Roller Pressure Feeder) System , which has removed all the drawbacks in the imported technologies. It provides smaller contact angle, reduced length of pressure chute, economic power consumption and better mill feeding, which gives increased crushing rate and better juice extraction. Conversion from 3 roller to 5 roller mill with SSTRPF or SSGRPF is done with minimum work of shifting, drive gearing and foundation changes.

Till now, SS Engineers has performed 150 such conversions of existing Three Roller Mills into Five/Six Roller Mills. The Sugar factories with SSTRPF fitted by SS Engineers, on 30" x 60" common Drive Mill Tandem, have achieved crush rates of over 4500 TCD @ 15% fiber, which is the highest in India with RME above 96%.